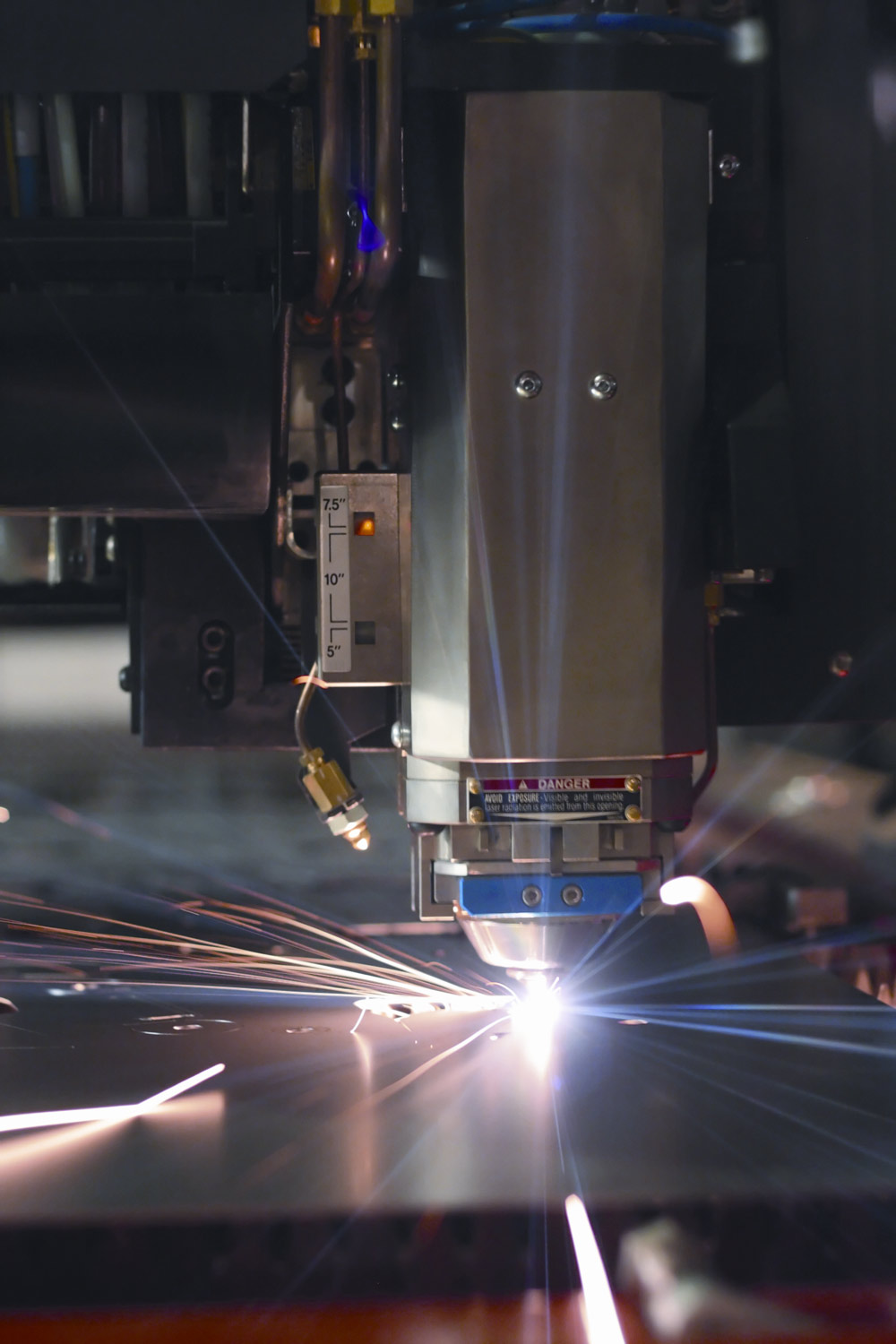

Nitrogen Generator For Laser Cutting

Our company also specializes in custom ultra high pressure nitrogen generators for laser cutting.

Nitrogen generator for laser cutting. For example an oxide layer can cause paint to adhere less strongly on non alloy steel. With pressures from 300 psi to over 500 psi we can design a system to meet any laser s demand. This can cause a carbon layer to form on the cut edge resulting in issues such as poor product finish and adhesion problems for any coating. Thanks to its inert properties nitrogen allows the laser to operate in an oxygen free environment without the risk of oxidation.

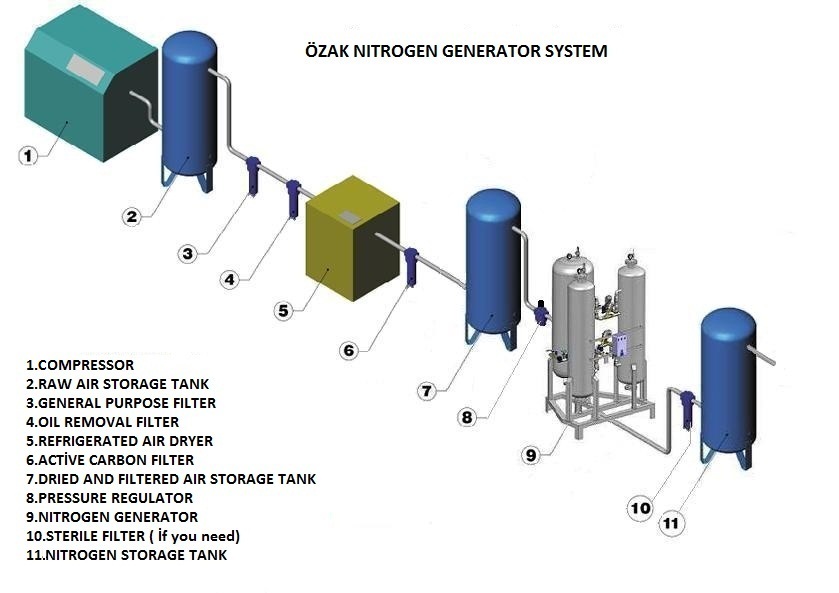

Here are some situations in which you can use laser cutting with a nitrogen generator such as generon s compact nitrogen generators. Using nitrogen during the laser cutting process can help reduce oxidation of metal surfaces and provide for a faster cleaner cut. Our systems can also generate the high pressure you require. Nitroswing laserpack on site nitrogen production for laser cutting.

We build nitrogen generators for laser cutting machines fiber lasers and co2 lasers. Nitrogen generators for laser cutting beam purge assist gas nitrogen is a dry inert gas used in a wide range of applications where oxygen may be harmful to the product or process such as laser cutting. If non alloy steel is painted after cutting the cutting gas should be nitrogen. These systems will generate nitrogen overnight into a bank of cylinders for use later the next day.

In order to meet the specific nitrogen requirements of the industrials of laser. Laser cutting overview at it s simplest laser cutting is the process by which metals including aluminum stainless steel and carbon steel are cut with a high powered laser beam. An essential element in this process is assist gas which is the gas that is used in the cutting process to ensure the quality performance of the laser. In contrast nitrogen cutting produces a clean edge.

Nitrogen generator nitrogen for laser cutting. Nitrogen generators for laser cutting deliver quick savings and quality cuts. Nitrogen assisted laser cutting is suitable for a wide range of applications. Cgt laser cutting with nitrogen is intended for applications where oxidation is not wanted.

Nitrogen is a gas widely used in laser cutting for its inert properties that prevent any reaction with the molten metal. Applications for nitrogen assisted laser cutting. Our nitrogen generators produce nitrogen from purities of 99 to 99 999. When your application heats up and comes in contact with oxygen a phenomenon known as oxidation occurs.

Nitrogen for laser cutting. Weldable steel components laser cut with oxygen will not pass the bending test. Mss nitrogen generators for laser cutting are well proven with over 100 lasers running in the uk with mss equipment.